How DEPCOM Builds Relationships with Suppliers That Foster Long-Term Growth

Headquartered in Scottsdale, Arizona, DEPCOM Power is responsible for the engineering, construction and operation of one gigawatt (GW) of utility solar plants for companies stretching from Oregon to Mississippi to North Carolina.

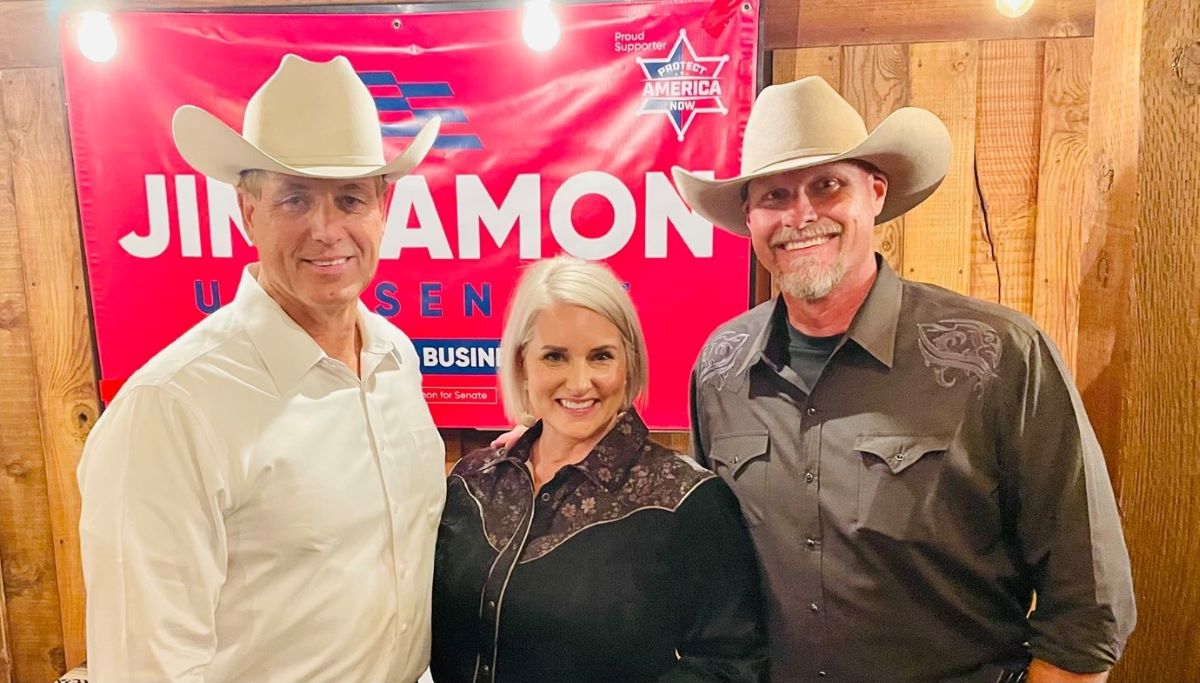

The company’s founder, Jim Lamon launched the company in 2013, after nearly three decades of experience working in the power industry, mostly in executive roles. Five years later, DEPCOM found itself ranked fifth on Inc. magazine’s list of America’s 500 fastest-growing private companies. Last year, DEPCOM was in top 15 Solar Power contractors that perform engineering, procurement and construction (EPC) work in the solar power industry with an annual revenue of more than $200 million.

The Founder’s Story: From Football to Power

Jim Lamon was taught early in life about responsibility, growing up on a farm in Alabama where daily chores were a given. “Everybody has their responsibilities on a family farm, and I learned a lot about the importance of that kind of regimen,” he says.

“My parents came from nothing. Dad grew up with no electricity or indoor plumbing. He then worked three jobs, getting a college education at night, with my mom right there by his side, working herself and raising two kids.”

He describes his parents as strong. And big. It’s not hard to imagine with Lamon, an imposing six feet, four inches tall, a height he reached in high school. A height that landed him a job in construction on the local highway at age 16. “I told them I was 18 to get the job and they didn’t question it,” he recalls. “I started as a laborer, showing up every day on time, working long hours, operating heavy construction equipment.”

“But as a big boy, about 200-ish pounds, I was recruited to play ball. So, I went to the University of Alabama, where I experienced two years of college football under Coach Bryant, who was a legend of the game.”

“He taught me about never doing anything halfway,” Lamon remembers. “He said that if you put your mind and your body to something and have a winning attitude, then you’ve got a great foundation for life. He coached us to get in every day and win. Not just as an individual but as a team member.”

After two years at university, Lamon swapped his football scholarship for an ROTC (Reserve Officer Training Corps) scholarship, serving in the military as an engineering officer in Army Airborne School, or Jump School, as it’s more widely known.“I needed to see the world,” he explains. “I spent six years with the military and, just before I exited, was an officer in Bavaria in charge of some fairly significant construction, expanding air bases to build as army units.”

His experience led him to be recruited by the Clark Construction Group, a company just launching into the power industry and one that favored ex-military officers. Starting as a field engineer, he worked his way up the ranks to Vice President of Operations.

“That’s how my interest in power was sparked, basically exiting the military and being recruited into a company that was just getting into power and finding I really enjoyed it.”

“One of the things that drives me is that power and energy are typically associated with a variety of people: tradesmen, craftsmen, engineers, planners and accountants. I’ve always enjoyed working hard to build teams and to motivate them to excellence. It’s very much how I was coached during my football days.

With Coach Bryant’s lessons always front of mind, Jim Lamon describes the decision to launch his own company as more exciting than difficult. There was no giving up halfway and he had to be the best.

“That meant recruiting the best people,” he says. “There’s a lot of adventure in that and it was probably my biggest surprise in starting a new company. Be it super-critical coal units, gas units, anything, great technology needs a great team to actually implement it; to bring it to reality.”

Lamon used his contacts to recruit industry veterans, nine of whom were poached from First Solar, where he used to work as the Executive Officer. It was a bold move for the new recruits, executives asked to leave behind six-figure salaries and bonus plans and agree to work their first year with no pay.

“When I look back on it, I’m a bit surprised in terms of my ability to get them over. But nine of my direct reports joined and these guys were really good at what they were doing. I think the appeal was the entrepreneurial environment offered, there was a strong team belief that we could do this.”

Doing Business in a Different Way

DEPCOM’s founding team believed in doing business a different way with suppliers. The team’s members believed the model of just bidding out all projects to a wide group and asking suppliers to respond to requests for quotations (RFQs) on singular projects wasn’t going to allow them to respond at the speed that modern business requires and wasn’t going to provide them the volume needed to drive toward the best-in-class cost structure that’s essential for success in the highly competitive solar EPC industry. From the company’s founding, DEPCOM’s founders reached out to potential supplier partners about forming relationships to work on several projects.

“I always view my role as much more than tactical execution,” says Mark Brown, DEPCOM’S vice president of procurement/supply chain. “It’s not just about today — it’s about today, tomorrow and next year. The only way to be successful in this industry is to make sure you’re always thinking strategically and never taking your eye off your long-term goals.”

From the beginning, DEPCOM targeted up-and-coming suppliers that hadn’t yet reached “top tier” status but had solid technology, were looking to grow quickly and shared the same corporate philosophy as DEPCOM.

“The sum must always be greater than the parts,” says Brown, when describing DEPCOM’s approach to supplier engagement. He adds that “intelligent risk taking” is also a key component to the company’s success. DEPCOM has partnered with several suppliers to bring their new technology and products to the mainstream industry.

“We believe in bringing exceptional value to our customers and one of the ways we do that is to make sure we use the absolute best technology and products in our power plants,” Brown says “We know how to assess technology and execution risk.”

Taking a long-term engagement approach with suppliers allows them to be more invested in your success Brown says. “I told them, ‘If we win business, then they win business,’” Brown says. “It was my job to sell them the vision of where we could go together.”

Not A Normal Start-up

DEPCOM wasn’t a normal start-up. Brown says he and his founding partners had established a successful track record in the industry and developed deep relationships with many potential suppliers from their days with First Solar, a manufacturer of solar panels and an industry player in utility-scale solar EPC.

Brown leveraged those relationships and the team’s track record, but those potential suppliers also liked DEPCOM’s “partnership” approach to supplier engagement. “Our discussions were about how we could jointly grow the business,” Brown says.

Like himself, he notes, many suppliers were growing tired of the old-school model of bidding on droves of individual projects and only winning a handful of them because they didn’t bid low enough.

“The solar power industry is one of the most competitive out there,” Brown says. “The old approach of bidding 10 jobs to win one just requires too much time and overhead to be successful in the long term. Being successful is much more than just having the lowest up-front cost.”

DEPCOM wanted to form a “collaborative consortium” with suppliers so they could openly discuss topics like cost curves, development cycles and lessons learned from the field so their suppliers could drive product innovation and identify all potential opportunities for driving down total overall cost of ownership.

“We’ve always believed in providing open and honest feedback to our supplier partners so they can develop better products for us and the rest of the industry,” Brown says. “We’re all in this together, striving to drive down the cost of solar power, which ultimately increases the potential market for all of us.”

‘Building Blocks’

Standardization is another best practice that DEPCOM promoted to suppliers. While Brown realizes that all power plants can’t be built the same, certain “building blocks” and “standard” products can be developed and used to build the plants. By leveraging this standardization, efficiencies in plant design and construction can be gained, material lead times can be reduced and suppliers can gain economies of scale, which drives down their production costs, Brown says And through partnerships with the same suppliers, DEPCOM has built a “library” of standard products and designs that serve as “building blocks” that can be used over again, which cuts down on complexities and keeps costs in check, he stresses.

When DEPCOM began, the first conversations its management team had were about what they needed to do to compete with other companies much bigger than they were and many of which had been in business for decades. Brown says the best practice of taking a partnership mentality with key suppliers struck a nerve and helped DEPCOM differentiate from its competitors.

“In order to succeed long term in our industry, it really does have to be about partnerships with the supply base. Nobody wins alone these days,” he says.

Strategies for Addressing Growth

When the project manager Andy Nyce first began working for DEPCOM Power almost six years ago, the company was only working on one or two projects at a time. But as the industry and the company has grown, the number of simultaneous projects being developed, constructed or commissioned– all large scale, 10 to 100 MW–has rapidly ballooned to more than 20 at the time of this writing.

“Whenever you experience rapid growth, you are moving faster than you might have imagined. I think with that comes a range of interesting challenges,” he says. “We were taking on larger and more complex projects and working in areas of the country that we hadn’t operated in before. There was certainly a learning curve for us, which has been really exciting.”

To manage growth, the company has implemented a number of new strategies, including process standardization and improved communication through regular and structured meetings between key personnel. The company has also focused on hiring temporary employees for projects.

DEPCOM Power has just over 150 full-time employees, but at any single time, the company may also hire 1,000 to 1,600 temporary construction workers.

“There’s a cyclical nature to solar construction,” Nyce says. “Even with all these jobs running, there are still times when we’re busier than others. Minimizing overhead is a core value for DEPCOM so that we can stay nimble during challenging times.”

Weekly Meetings, Tracking Tools, Lessons Learned

To ensure comprehensive and accurate communication between the various functions of the business, the company schedules weekly meetings and has implemented a variety of unique tracking tools. The goal of these efforts is to ensure that team members stay on track with their tasks, understand their priorities and give various stakeholders insight into all the operations of the company. In addition, the aim is to give personnel the opportunity to ask questions and learn from their peers.

“We implemented initiatives such as ‘lessons learned,’ along with ‘end of project reviews,’ sharing lessons learned throughout the entire team so that we are all continually improving,” he says.

The tracking tools include Smartsheet and QuickBase, which allow the company to combine information from different sources into a single dashboard.

“This is a huge improvement and means that when we run our internal meetings, everyone has access to the same information in the same format,” says Nyce.

Team Spirit: Owners Instead of Employees

The company’s 150 permanent engineers, designers and operations staff all have their own skin in the game as owners. “All DEPCOM team members are given shares in the company,” Jim Lamon states.

“Our goal is that DEPCOM staff act like owners rather than employees. “They’re shareholders and owners working together each day to be national champions. They don’t want to just get the job done but to be the best in the industry. We want everyone to fully embrace being the best in customer service as this is the source of our income. Even our staff bonus system is linked to our customer satisfaction surveys.”

Lamon is proud of DEPCOM’s safety culture and industry-leading health, safety and environmental practices. In fact, every DEPCOM meeting, and job site day is started with a ‘Safety Moment’ with the belief that all occupational injuries are preventable. “I work hard to be a good mentor and coach,” he says.

“I want to help the team make the most of their talents and reach their ultimate level. We move them into positions they can be more successful in and give them the training they need. We stretch them to grow continuously.”

DEPCOM actively works with suppliers and partners to shift its supply chain to local sources. This provides good risk mitigation and minimizes supply chain disruption. “Having shorter domestic supply chains has helped throughout the COVID-19 pandemic,” Lamon suggests.

“Price, quality, delivery and a history of meeting commitments are key measures of our supplier partnerships. Some of our suppliers have even incorporated DEPCOM core values into their own. I’m also very proud that a few DEPCOM teammates have left to form their own subcontracting firms and are now hired to work on DEPCOM projects.”

The Heart of Giving Back

From the very beginning, Jim Lamon and the founding team at DEPCOM wanted to demonstrate the company’s integrity by committing to “doing the right thing even when it’s hard”. Equally, their civic responsibility continues to be a cornerstone of the company’s foundations.

The DEPCOM team has a big heart for making a difference and are proud of the positive impact they can make in the communities they work in. “Giving back is one of our core values,” he states.

“Collectively, we give 10% of our net income to the most in need across the country. We’ve given US$7 million over 80 months.” Not-for-profit DEPCOM GIVES was established to manage the stewardship of this charitable giving.

“We get deeply involved in the community through our retired pastor on staff, who personally focuses on distributing donations and volunteer efforts for non-profits,” Lamon says. “We support veteran organizations, the impoverished, and education programs and community solar.”

Today, DEPCOM provides low-cost, high-quality utility-scale solar energy, its employees are owners, it supports the American economy, employs veterans and generously gives to charity. It does all of this while driving down the cost of electricity for US ratepayers. “Doing the right thing” is just what DEPCOM does.