Challenges Face Nuclear Power to Become a Trusted Ally

Since nuclear energy began in 1951, there have been around 30 reported accidents worldwide. Most were minor, but the devastating incidents at Fukushima and Chernobyl changed everything. These disasters significantly shifted public perception, leading many to view nuclear energy as inherently dangerous.

Since then, the technology has been a source of anxiety for many. It involves tapping into ancient, hazardous minerals to harness powerful and unnatural forces, creating highly toxic elements. If these elements were to escape, they could cause severe harm and even death, as history has shown.

However, all the meltdowns in the past happed because of the malfunctions in the nuclear plant systems, and the fact is these errors can be solved.

“Why do we need to solve these problems to get close to the Satan?” is the question you may ask.

Well, despite its risks as a catastrophic weapon, nuclear power holds the future of a real climate change fighter. To understand why this technology can serve as a new way to tackle global warming, we need to get into the fundamentals.

Why Can Nuclear Power Solve the Problem of Climate Change?

To address rapid climate change, the world must cut greenhouse gas emissions to net zero. In 2018, energy production was responsible for 73% of global emissions, mainly due to burning fossil fuels.

Energy use spans a wide array of activities, including transportation, manufacturing, and heating. Currently, 84% of the world’s primary energy comes from fossil fuels: 33% from oil, 27% from coal, and 24% from natural gas. Notably, about 10% of global oil consumption is used solely for heating homes.

Low-emission sources account for only about 16% of global energy: nearly 7% from hydroelectric power, 5% from a combination of solar, wind, bioenergy, wave, tidal, and geothermal energy, and approximately 4% from nuclear power. This heavy reliance on coal, oil, and gas poses significant challenges for transitioning to cleaner energy sources.

To reduce reliance on fossil fuels, one of the most effective strategies is to electrify as many sectors as possible. Electricity powers our devices and is vital for modern life. Industries need to switch from burning fossil fuels to using electricity, from electric cars to electric heaters. The advantage of electricity is that it can be generated from low-emission sources like solar, wind, and nuclear power, making it a crucial tool for a radical energy transition.

However, several challenges make this shift difficult. Firstly, in many regions, electricity is still primarily produced by burning fossil fuels. Additionally, global electricity usage has increased by 73% over the last 20 years, adding to the complexity of transitioning to cleaner energy sources.

Despite installing renewable energy sources at record speeds, the amount of fossil fuels burned for electricity continues to rise each year. Renewables have not yet been able to keep up with the increasing demand for electricity, resulting in rising emissions worldwide.

An alternative to fossil fuels is nuclear power. Although not renewable, nuclear power produces minimal greenhouse gas emissions compared to fossil fuels. Over the past five decades, nuclear power has prevented the release of 50 gigatons of carbon dioxide, equivalent to two years’ worth of global energy-related emissions.

Despite its clear climate change fighting potential, over the past 20 years, nuclear power has stagnated, and there are reasons for this.

The Problems that Block the Evolution of Nuclear Power

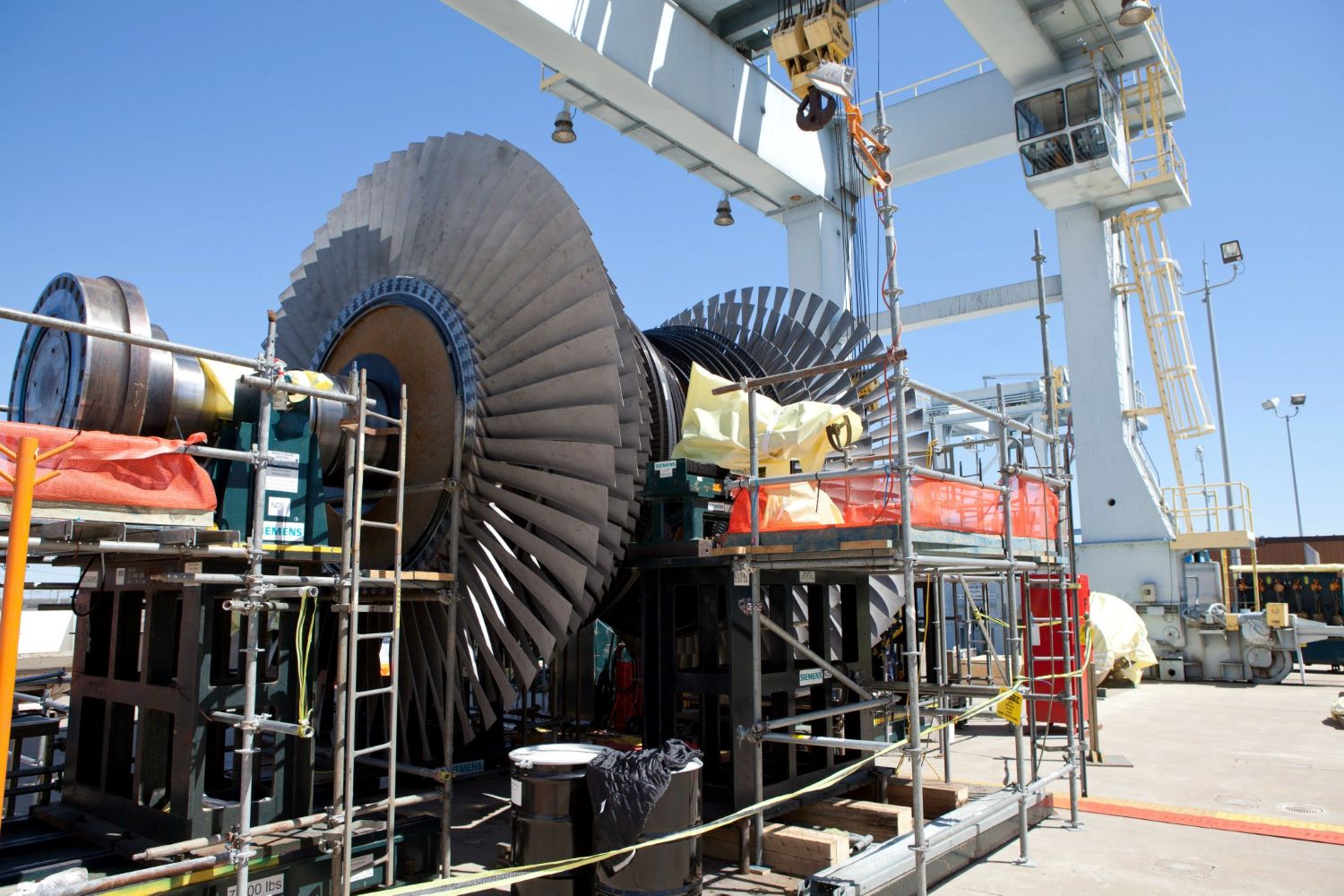

Nuclear power is the most potent tool available to halt human-driven climate change. However, its inherent risks have hindered political will to invest in the technology. For nuclear power to thrive and help address our planet’s greatest challenge, it must evolve. The first major obstacle to this evolution is the coolant systems.

Cooling Systems and Human Errors – the Core of Possible Disasters

Many of the most notorious nuclear meltdowns have been caused by failures in coolant systems. The Three Mile Island partial meltdown incident of 1979 is a typical example

The incident began with a mechanical failure in the plant’s cooling system. A clogged filter prevented water from reaching the steam generator, causing the reactor’s temperature and pressure to rise. A relief valve malfunctioned, staying open and allowing coolant to escape, further increasing temperatures. Reactor operators received conflicting information and were hindered by blocked emergency water systems due to closed valves that were not reopened after maintenance.

The operator failed to notice the closed valves, which violated NRC regulations requiring reactor shutdown in such cases. The incident, exacerbated by human error, underscores the critical need for reliable mechanical safety systems and impeccable control measures in nuclear power plants. It highlights the importance of attention to detail in design to prevent catastrophic meltdowns, emphasizing that there is no room for human error in nuclear safety.

In Fukushima, an earthquake and its resulting tsunami knocked out the plant’s cooling systems. The cooling systems in Fukushima depended on a separate energy source. The pumps that were needed to cool the reactors lost power, resulting in a catastrophic meltdown. The plant did have a backup system, which also failed. This need for external power to cool the reactors was a key disadvantage of the design. Fukushima also highlighted a weakness of current nuclear reactors, the use of water as a coolant.

Liquid water is a great conductor of heat and serves as a fantastic cooling agent. However, when control is lost, this water can lead to a high-pressure steam explosion, spreading radioactive materials across vast distances.

Nuclear Power Waste – the Catastrophe to the Environment

Light-water reactors operate using an open fuel cycle. In this cycle, uranium is mined, processed, enriched, used, and then stored as radioactive waste, which governments struggle to manage. In the US, there has been a plan to create deep geological storage facilities 660 meters below Yucca Mountain to address this issue.

Since the 1980s, there has been a plan to create deep geological storage facilities below Yucca Mountain to manage nuclear waste in the US. However, this plan has not been implemented, leading to nuclear fuel being stored in interim facilities across the country. Like many nuclear energy projects, it has faced delays and a lack of funding. Presidents Obama, Trump, and Biden have all failed to address this impending ecological threat.

Waste management issues have consistently sparked political turmoil. For example, shipments of nuclear waste from France to Germany have been met with thousands of protestors, illustrating the significant political resistance to nuclear energy development.

Lack of Funding – The Crazy Costs of Nuclear Power

The adoption of nuclear energy remains constrained by its high capital costs, making it inaccessible for many countries.

The cost breakdown of nuclear power includes capital and operating expenses. Capital costs encompass site preparation, engineering, construction, commissioning, and financing, while operating costs include fuel, maintenance, decommissioning, and waste disposal.

Compared to coal and natural gas plants, nuclear power plants typically incur higher capital costs due to their technical complexity and stringent licensing requirements. The lengthy design and construction process also drives up financing expenses, often exceeding construction costs, particularly when faced with delays due to design changes or legal disputes.

These substantial capital costs have hindered the economic competitiveness of nuclear power in the United States, especially against natural gas alternatives. Consequently, there has been a decline in new nuclear plant construction, with only Watts Bar 2 becoming operational in the past two decades.

In 2017, two South Carolina utilities abandoned Westinghouse AP1000 reactors due to manufacturing issues, delays, and cost overruns. Currently, only two AP1000 reactors in Georgia remain under construction, grappling with similar challenges as costs escalate from $14 billion to $23 billion. Nevertheless, construction persists with government financial backing despite these hurdles.

Nuclear power’s challenges in the U.S. stem largely from its high discount rate, which has a considerable impact on the overall energy cost assessment. This effect is more pronounced for nuclear power compared to natural gas or coal-fired plants, primarily due to the significant construction costs associated with nuclear energy.

How Can These Roadblocks Be Tackled?

When we look at those roadblocks mentioned above, it may lead to the uncertain future of nuclear power. However, these problems can be solved.

The Way Out for Nuclear Power Coolant Systems and Waste

Today’s new nuclear reactors focus on two key areas: passive cooling and enhanced thermal efficiencies using high-temperature coolants. Unlike traditional reactors limited by lower temperature thresholds, future designs target higher efficiency by employing coolants capable of withstanding elevated temperatures.

Thermal efficiency, vital for converting thermal energy into electricity, typically improves with higher temperatures. To achieve this, new nuclear reactors are exploring alternative coolant materials capable of enduring these elevated temperatures.

In the early 2000s, the US Department of Energy launched the Gen IV International Forum, convening top scientists worldwide to steer policy decisions and funding for innovative reactor designs. Six promising technologies were selected and termed Generation IV reactors.

Instead of using water as a coolant, Gen IV reactors can use gas, supercritical water, molten salts, molten lead, or sodium to increase the operating temperature of the reactor. This increase in efficiency will result in less nuclear waste per gigawatt generated, but these designs also aim to increase passive cooling capabilities and limit nuclear proliferation risks.

Molten salt reactors (MSRs) offer an innovative approach to nuclear energy, where both the coolant and the radioactive material are combined. Initially tested in the 1960s at Oak Ridge National Laboratory, MSRs utilize nuclear fuel dissolved in a molten salt mixture. The fuel salt circulates through the reactor core, absorbing heat from nuclear fission and transferring it to a secondary salt coolant loop, which then heats water in a steam generator.

MSRs have several advantages over traditional light-water reactors. They operate at lower pressures, reducing the risk of high-temperature steam explosions, and promise higher thermal efficiency, potentially achieving 40-45%. MSRs can perform inline fuel processing, continuously removing fission products and adding new fuel, enabling uninterrupted operation.

Even if pump failures occur, MSRs can safely cool down. The salts’ properties naturally inhibit further fission as temperatures rise, and a freeze plug at the bottom of the salt pool allows the molten salt to drain into cooled dump tanks, preventing meltdowns.

Cost Solution- Standardized Designs and Downsized Reactors

Since 2003, MIT has been conducting studies aimed at guiding the future of nuclear energy. In their latest report, they emphasized the urgent need to reduce the cost of nuclear plants. Consequently, the most promising ideas are focused on addressing these cost challenges.

While deep geological repositories, uranium reprocessing, and Gen IV reactors dominated nuclear discussions in the 20th century, a new design concept emerged in the early 2000s: Small Modular Reactors (SMRs).

The aim of SMRs is to shrink reactors into small, standardized modules that can be manufactured in factories. This approach not only has the potential to reduce costs but also enhances reliability and safety by simplifying manufacturing and assembly, while lowering on-site construction expenses.

Small modular reactors (SMRs) operate similarly to conventional nuclear plants, but with smaller individual reactors that can function in expandable modules. This modular approach allows for the gradual increase of a power plant’s output using cheaper factory-made modules, rather than constructing one large custom-designed nuclear power plant with a 1000 Megawatt capacity.

Plus, the smaller size of SMRs offers a significant advantage in passive safety. With a greater surface area-to-volume ratio, smaller reactors facilitate more efficient heat transfer. This means that natural convection cycles become sufficient to cool the reactor. As the coolant heats up, it rises due to its lower density, establishing a natural flow pattern that drives the cooling process. This inherent safety feature reduces reliance on active cooling systems and enhances the overall safety of SMRs.

Small modular reactors (SMRs) are not defined by a single type of nuclear reactor or design; instead, they encompass a range of designs that capitalize on technology miniaturization. As a result, each SMR is unique, with variations in reactor types and designs. Some SMRs utilize Gen IV reactors, while others rely on light-water reactors.

Presently, there are over 70 commercial small modular reactors in various stages of development, and among these, NuScale stands out as one of the most promising companies.

NuScale – Takes the Lead

Their latest 77MW module measures approximately 20 meters in height and 4.5 meters in diameter. Each module is lowered into a water bath and placed on top of seismic isolators to safeguard the reactor against earthquakes. All components necessary for the nuclear reaction are housed within a single steel containment vessel.

To scale up the plant, multiple modules are interconnected. In the event of a power loss, control rods automatically descend using a gravity-driven mechanism, and the containment vessel seals its valves to isolate itself. The water from the core is boiled off as steam but remains within the containment vessel.

Utilizing an outside cooling pool to transfer heat, the steam condenses and accumulates at the bottom of the reactor vessel, establishing a natural circulation of cooling water within the steel containment vessel. Within seconds, both energy and temperature significantly decrease, with thermal power dropping by 90% within a day, followed by gradual cooling of the remaining 10% over several weeks.

Despite these promising features, commercial deployment is still a distant prospect. NuScale, although the most advanced, has only succeeded in creating a one-third scale model of their power plant.

Other Countries Joined the Game of SMRs

Various nations, including Russia, China, France, and South Korea, have invested in developing small modular reactor (SMR) technologies, but they’ve faced challenges in finding utility customers. In a capitalist system, without potential buyers, these ventures struggle. Even NuScale, a prominent player, has lost some utility clients due to pricing exceeding expectations.

This predicament is particularly daunting for companies banking on large-scale standardized factories to gain market traction. A catch-22 emerges: to establish the factory, they need customers, but without customers, justifying factory construction becomes difficult.

Unlocking economies of scale requires the construction of thousands of reactors, a feat traditional nuclear plants have leveraged to deliver cost-effective electricity. The key metric in attracting grid operators to purchase electricity lies in reducing the cost per megawatt. NuScale initially targeted a price point of $55/MWh, but inflation, rising steel costs, development issues, and delays have pushed costs to an estimated $100/MWh, while onshore wind and solar can be as cheap as $30/MWh.

Despite these challenges, investing in SMR technologies remains crucial for ensuring energy security and supporting global economies. The pursuit isn’t exclusive to the US; China is advancing with a functional SMR project, albeit with escalated costs compared to traditional large-scale nuclear plants.

Canada has also taken steps by formulating a 2020 SMR action plan and injecting millions into SMR startups to mitigate costs. However, substantial funding is essential to further develop these technologies, signaling incremental progress.