The Avant-Garde OSARO Gives an Arm to Logistics Operators

Artificial intelligence is all that scientists and businesspeople talk about in today’s society. For years, we’ve been taught that artificial intelligence is taking over the world. According to predictions, about half of all employment in the United States could be automated by the mid-2030s.

Although robots are not yet ready to “rule”, advances in machine learning are preparing the mechanical components of the workforce for more complex and autonomous tasks. OSARO is joining this “hype” as a startup that focuses on deep reinforcement learning systems and artificial intelligence for industrial robots.

Derik Pridmore founded the company in 2015, and it develops machine intelligence software that combines cutting-edge vision with robust adaptive decision-making capabilities to assist computer and robotic systems in acting effectively and intelligently.

Derik Pridmore abandoned a high-paying position in banking to pursue this promising area of technology. However, what is the tenet insight that dazzled him ended with a question mark. Let’s go through this article to learn about his OSARO journey.

From Clueless to The Only in Town

“I guess I’d start by saying I consider myself to be a technologist.” said Derik Pridmore.

Derik earned a master’s degree in computer science and electrical engineering from MIT in 2004. He subsequently pursued a decade-long career in finance, working in derivative trading units at JP Morgan before shifting to a hedge fund, building on his education in physics and computer science.

This man approached Peter Thiel’s hedge firm Clarium Capital Management in 2009 as Vice President to explore developments in a new subject called deep learning. To focus on the area, Thiel offered Derik a position as the Principal at the venture firm Founders Fund.

Deep learning is a particular kind of machine learning, which is essentially a three- or more-layered neural network. These neural networks seek to imitate the activity of the human brain, albeit with limited success, allowing it to “learn” from enormous volumes of data. While a single-layer neural network can still make approximate predictions, extra hidden layers can help enhance and improve accuracy.

Sensing his opportunity in the field, Derik realized that deep reinforcement learning could open up an array of applications previously unavailable to machines. Derik believed the technique may change the use of robotics in a variety of industries.

However, he was concerned about the numerous barriers to applying the technology to a new use case, such as productizing a new technology, selling the product, retaining the best talent, and dealing with risks from competitors on all sides.

Derik was also concerned with increasing manufacturing and balancing advancement with an emphasis on product sales. When he started, Derik did not even know what his product would be.

Derik cofounded OSARO in 2015 with Michael Kahane to commercialize deep learning technology in novel applications. Michael was previously a serial entrepreneur with a background in chip design.

Their initial effort was a proof of concept that demonstrated how a mix of deep learning and “imitation learning” based on observations of a human playing Atari could speed up machine learning by 100 times.

With the help of this demo, OSARO raised a seed round in March 2015 from Peter Thiel, Jerry Yang, Sean Parker, and others to pursue their dream.

Soon after, they initiated a pilot project with KUKA, a German industrial robot manufacturer. “Social media advertising and robotics sound insanely different,” said Derik, “but the unbelievably true thing is that the core technology is the same.”

They sent an OSARO robot to program under a scheme in which KUKA shared robots with external partners to promote innovation.

According to Derik, “We not only succeeded, but we did it with a very small amount of data, and we actually did it in a very robust way. We were able to pick the object up even if we moved it in adversarial positions. That impressed them.”

Now, OSARO has gone beyond all the initial expectations, thanks to the mission that always lighting the path to success and a product that’s worth it.

Lean Hard to Deep Learning to Power Robots

OSARO has been developing their product even before the pandemic, but when the crisis resonated, people started to understand why we need mass automation to pandemic-proof the supply chain.

That moment paved the way for the startup to make some headlines. But its product is still a top-notch advance even when the pandemic is long gone.

First, the technology OSARO uses, deep reinforcement learning, is a “bleeding edge” machine learning technique that most firms do not have the capability to use.

Furthermore, the few companies that use deep reinforcement learning, such as Google, typically learn from scratch with slow-to-train algorithms.

In certain circumstances, such as Sergey Levine’s work on grasping, they are able to overcome this constraint by employing a large number of robots that have been trained for many hours using learning algorithms.

In actuality, robotics is a major player in the field. Today, robots are essentially sold without a brain, and we can discuss this further.

To apply them to new domains, you must be able to do closed-loop control, which means taking perceptual data from a camera and controlling the robot. Deep learning excels at this type of problem solving. There’s also the notion of control, which is akin to reinforcement learning.

OSARO’s robot arm can undertake a unique type of Sisyphean task. It has the ability to hover above a gleaming mound of cooked chicken parts, drop down, and retrieve a single piece. After a brief moment, it swings around and gently places the chunk of chicken into a bento box moving along a conveyor belt.

This robot is more intelligent than any you’ve ever seen. The software has been programmed to pick and place chicken in under five seconds. OSARO wants its robots to find work in a Japanese food business within a year.

The AI software that operates OSARO’s robot allows it to recognize items in its direction, examine how they react when poked, pushed, and gripped, and then decide how to manage them. It, like other AI algorithms, learns via experience.

It figures out how to grip things successfully by using an off-the-shelf camera in conjunction with machine-learning software on a powerful computer nearby. With enough trial and error, the arm can learn to grab almost anything it encounters.

AI-enabled workplace robots will allow automation to infiltrate many more areas of labor. They could be used to replace people whenever products need to be sorted, unpacked, or boxed. They might take up more manufacturing jobs if they can manage a chaotic production floor.

By embedding AI software in a physical body, it can perform sight recognition, speech recognition, and navigation in the actual environment. It’s a revolution not only for robots, but also for artificial intelligence. And OSARO is riding that wave and successfully building up a product that can be implemented in any industry that needs to free up the burden on the workforce.

Lower Prices Through Less Labor Input

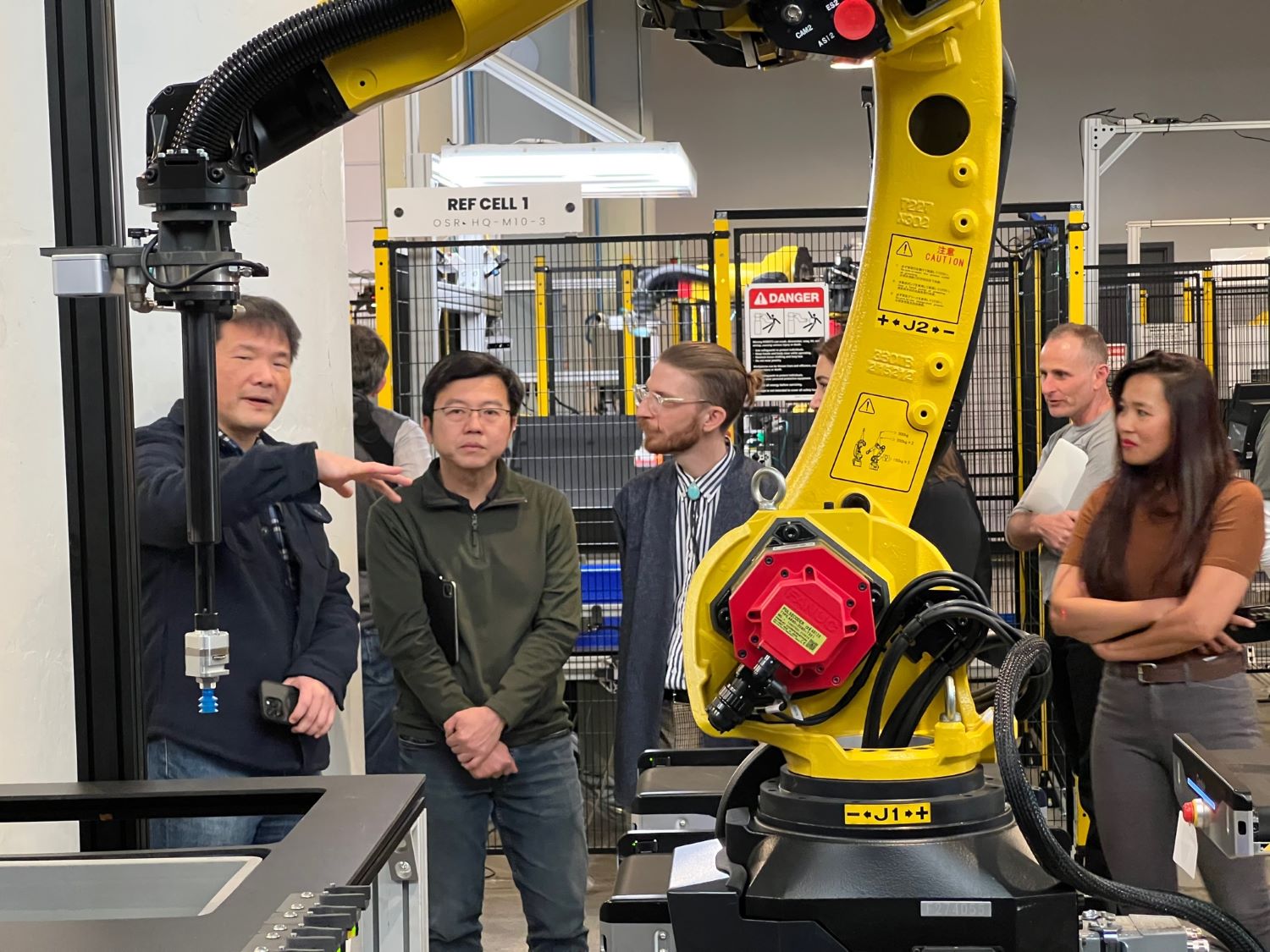

The company collaborates directly with warehouse technology suppliers to simplify and accelerate the most typical manual operations in distribution centers and manufacturing facilities, such as product and part selection and placement.

OSARO’s program, like many modern machine learning methods, automatically extracts information from high-dimensional, time-varying data. OSARO goes beyond simply categorizing data. The technology interacts with its surroundings in order to learn, explore, and achieve a specified goal.

OSARO frees humans to focus time, energy, and money on higher level activities by making machines more flexible, intelligent, and efficient.

OSARO Pick, the company’s flagship product, automates the stationary picking stations in goods-to-robot distribution hubs. OSARO claims to have numerous customers in e-commerce order fulfillment and intralogistics, and it hopes to grow into order fulfillment in electronics, clothes, grocery, medicines, and other industries.

“A key element of our competitive advantage is OSARO Vision’s deep learning algorithms,” said OSARO CEO Derik Pridmore.

He added, “These algorithms generalize picking tasks with minimal training data and no SKU registration for quick, scalable solutions. In addition, as a software company, we support a wide array of commodity hardware and robotic arms which lets our customers select options that best fit their needs.”

It’s not a boast to say that the key competitive point of OSARO is speed.

“From my perspective, what OSARO is doing that makes them stand out is the speed,” says Simon Goh, Director of Distribution and Facilities at Zenni Optical, a client of OSARO.

He added, “Because I know that other robots can do the same thing, but just when I look at their speed, it wasn’t that good. But OSARO, they can do it. The vision equipment and software can see the style and determine what kind of material and also the way they’re designed, they can actually pick anything with the right tool. So, the speed is making the difference.”

When Goh crunched the ROI numbers, he discovered that the OSARO robotic installation would reach a break-even point when compared to the current cost of human labor performing five steps at speed.

Zenni could do it any way, with people or with robots, and cost around the same amount. However, labor costs are rising while technology costs are falling, making the break-even point for Goh to strike and make a move. And, as manufacturers of robotics like to point out, a robot never takes a sick day or a vacation.

That’s just the first step in the journey to save money for their clients.

One feature of OSARO is that its software is compatible with existing robotics control systems. OSARO created the integrations required to work with robots from every major manufacturer. Different Application Programming Interfaces (APIs) were used to control robots made by different manufacturers.

OSARO tailored their models to whichever robots and end effectors the integrator chose for a specific application.

By employing advanced machine learning to handle lower-quality data, OSARO’s solution could function on basic GPU, unlike many competitors that required higher-end controllers, and used just commodity 3D cameras, as opposed to high-end manufacturing grade cameras (e.g. 3D structured light sensors).

Derik stated, “We are convincing people that machine learning has progressed to the point where you need to make almost no hardware. We can build models that fit between super cheap sensors.” OSARO saw compatibility as a key competitive advantage to disrupt from below.

OSARO’s system was expected to pay for itself in two to three years, with customers saving at least 50% on labor expenditures over the first five years.

OSARO frees humans to focus time, energy, and money on higher level activities by making machines more flexible, intelligent, and efficient. This is what everyone who uses the startup’s solution desires. This is also the key to their financial abundance.

Snap in Abundance for Transitioning the Industry

Derik Pridmore once said that “I would say stay focused on your customer and the problem, and don’t be wedded to any particular technique.”

He continued, “It’s nice to come in with some priors—whether it’s technical expertise or hypothesis about what technique it will take to make it work—but you should remain flexible, because you’re going to learn a lot about your problem as soon as you get started working on it. You’re going to want to build the simplest system you can that gets the job done. So don’t overkill.”

OSARO always puts customers at the core to develop its products, this is also the reason for its appealing presence in investors’ eyes.

On March 2015, OSARO announced raising an undisclosed amount of seed funding from Morado Ventures. This cash played a big role in shaping the company and extending its name to the industry.

Later, on December 2015, OSARO announced raising a second seed funding round with $3.3 million in funding from ZhenFund, La Famiglia, Morado Ventures, Sean Parker, Scott Banister, Peter Thiel, Nicolas Berggruen, Konstantin von Unger, Jerry Yang, and Elad Gil. The second seed round was raised before OSARO had any customers.

The startup came to Series A in April 2017 when OSARO announced raising $10 million in series A funding from iRobot Ventures, ZhenFund, Pegasus Tech Ventures, Compound, Comcast Ventures, Abstract Ventures, and AAF Management.

In October 2019, OSARO announced raising $16 million in series B funding from King River Capital (lead investor), Pegasus Tech Ventures, Morado Ventures, Global IoT Technology Ventures, Founders Fund, Compound, Comcast Ventures, Alpha Intelligence, and AME Cloud Ventures. The company plans on using their series B funding to expand their operations globally.

The latest round was on August 18, 2021, since the company announced the completion of a series C funding round led by Octave Ventures. The new round brings OSARO’s total funding to date to $67.5 million.

New investors include Octave Ventures, J17 Capital, and Tomales Bay Capital. Existing investors AME Cloud Ventures, iRobot Corporation, King River Capital, and Founders Fund also participated.

OSARO intends to leverage this additional investment to accelerate worldwide growth by expanding its market presence and hiring, as well as expanding its solution and support capabilities.

In addition, the company will continue to improve its core technical capabilities, such as incorporating its machine learning platform into new automation applications.

Currently, OSARO’s solutions enable logistics operators to scale e-commerce order fulfillment, inventory induction and extraction, sortation, and singulation.

The robotic automation from the company integrates with ASRS, AMRs, conveyor systems, and other materials handling equipment.

OSARO is just at the beginning of the game, and the company well-acknowledged this. This is why the startup always upgrades its products to meet the demand that’s only rising.

Launch the First Robotic Solution for Automated Bagging

On March 2022, OSARO launched the first comprehensive robotics solution for automated bagging at MODEX 2022.

The OSARO Automated Bagging Solution combines OSARO software-powered robots with automatic bagging machines from prominent manufacturers such as PAC Machinery and Pregis.

To fulfill orders swiftly and efficiently, OSARO’s autonomous piece-picking robot interfaces easily with current logistical facilities. It is immediately available as a ‘drop-in’ upgrade to existing or new fulfillment operations.

“Warehouse and logistics operations globally are wrestling with an acceleration of consumer demand and a shortage of labor,” said Derik Pridmore, CEO of OSARO.

He also said, “By automating common manual processes such as movement, storage and retrieval, and picking and placing, fulfillment centers and e-commerce operations can become more efficient and cost effective—and improve employee safety.”

Unlike traditional automation technologies, OSARO’s system provides unparalleled object detection and manipulation, enhancing bagging productivity and bringing strong and efficient automation to a wide range of e-commerce applications.

It is capable of packing and shipping a wide range of e-commerce items at a rate of 350 parts per hour while operating with minimum human oversight 24 hours a day, seven days a week.

Fulfillment centers, warehouses, and direct-to-consumer (DTC) e-commerce centers may now improve and speed order fulfillment by combining OSARO’s advanced pick-and-place robotics with a variety of packing equipment from the industry’s leading automatic bagging manufacturers.

Bottom lines

OSARO went after warehousing, already an exciting field for robotics and automation, for its initial product—a system which could enable robotic arms to “pick and place” individual items into boxes that would be shipped to consumers.

According to a Research and Markets research, the global collaborative robot (cobot) market is predicted to increase from $1.1 billion in 2022 to whoppingly $9.2 billion in 2028, at a compound yearly growth rate of 41.5% from 2022 to 2028.

As the game is getting “needy”, whether to stuff boxes of snacks as well as to fill a row of fast-moving vaccine vials, more companies are switching to robots for the labor-intensive, repetitive tasks. In the market that’s getting hotter, OSARO has already made the news several times for using novel methods for machine learning. Let’s see how they’re going to compete against these rivals to grab the best seat at the table.