Crisis to Calibration: Tom Arseneault’s Tactical Mastery at BAE Systems

The defense industry stands at the forefront of technological advancements, with a constant commitment to fulfilling critical and complex missions.

BAE Systems is a key player in this sector, leveraging innovation and expertise to address the dynamic challenges faced by nations worldwide. As a leader in defense, security, and aerospace solutions, the company’s contributions extend across international borders, making it an integral part of safeguarding global interests.

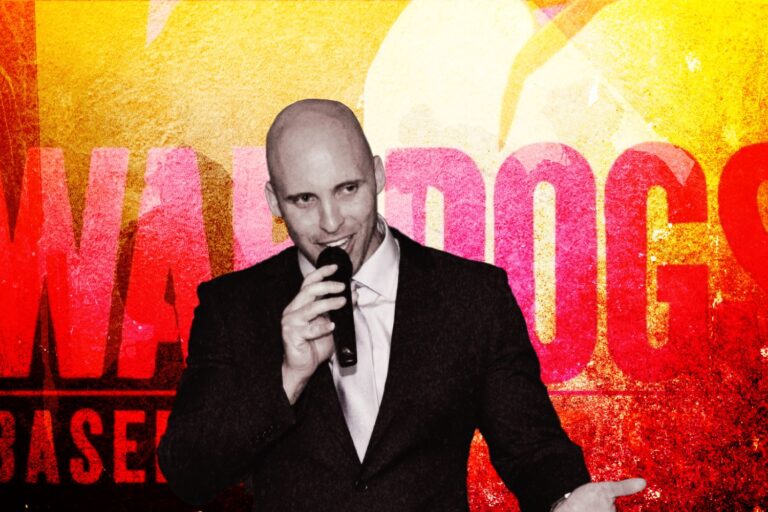

At the helm of this transformative period for BAE Systems is Tom Arseneault, a seasoned professional with a proven track record in leading complex organizations.

Big Shot in the Game: Yearslong Architect an Empire

Holding bachelor’s and master’s degrees in electrical engineering from Worcester Polytechnic Institute (WPI), and an MBA from Boston University, Arseneault’s educational journey laid the foundation for his multifaceted contributions to the defense and technology sectors.

Before assuming a pivotal role at BAE Systems, Tom Arseneault forged a path of leadership and innovation through his tenure at industry giants Lockheed Martin, General Electric, and TASC.

Arseneault’s experience at Lockheed Martin, a global aerospace and defense company, laid the foundation for his leadership prowess. Serving in senior leadership positions at Lockheed Martin, he honed his skills in navigating the complexities of the aerospace and defense industry.

General Electric (GE), a conglomerate with a diverse range of businesses, also benefited from Arseneault’s expertise during the earlier stages of his career.

His roles at GE, a company renowned for its innovation in various sectors, added breadth to his leadership experience. Managing responsibilities in engineering and program management, Arseneault further developed his capacity to address multifaceted challenges inherent in large-scale enterprises.

Transitioning to TASC (formerly part of Northrop Grumman and later acquired by Engility Holdings, Inc.), Arseneault continued to refine his leadership skills. TASC, a provider of advanced systems engineering and decision-support services, provided him with exposure to cutting-edge technologies and complex projects.

On April 1, 2020, BAE Systems Inc., the American subsidiary of the global defense, security, and aerospace giant BAE Systems plc, announced a significant leadership transition.

Tom Arseneault, the current Chief Operating Officer (COO) and President, is set to assume the role of CEO and President, signaling a new era of leadership for the company.

Jerry DeMuro, the outgoing CEO, will transition to a pivotal role as the Executive Vice President of Strategic Initiatives.

Under Tom Arseneault’s leadership, BAE Systems Inc. is poised to navigate the complex landscape of defense, security, and aerospace.

Dual Challenge Response in Pandemic and Ukraine Conflict

Arseneault took the reins at BAE right as the pandemic was heating up. It rocked the defense industry in many ways, encompassing social distancing mandates, disruptions in supply chains, and the specter of inflation.

So how did he try to set BAE on a course to withstand that turmoil?

“My timing was impeccable. It all comes down to making sure we’re focusing on our workforce in a way that allows them to be, initially, safe in the way they execute their roles,” he said.

Initially prioritizing the safety of the workforce, Arseneault emphasized the implementation of stringent safety measures aligned with CDC guidelines. This included providing necessary tools, equipment, and personal protective gear, instilling trust among employees that both BAE Systems and the government were deeply committed to their health and well-being.

“We are the defense-industrial base writ large, from companies of size, right down through many layers of the supply chain. And that collective workforce is what really rocked through this period. The concerns about personal safety, ensuring we were going to be able to continue to work right through the pandemic,” he said.

As the pandemic unfolded, Arseneault’s leadership evolved to address the shifting dynamics of workforce challenges. A crucial aspect involved adapting to the need for flexibility, acknowledging the varied nature of tasks within the defense industry.

He highlighted the inherent limitations of remote work in certain scenarios, emphasizing that critical activities, such as repairing a ship, building electronic warfare systems, or working on highly classified projects, necessitated a physical presence.

Moreover, Arseneault acknowledged the enduring challenges stemming from inflation affecting the supply chain.

“Things seem to have stabilized on the grand scale; however, there continue to be new challenges mounting. COVID shone a light on how susceptible the industry was to supply chain disruption, because COVID rippled up and down through every layer, and particularly in smaller businesses where you take out five or 10 people and you basically shut their production line down for a period of time,” he stated.

As the defense industry grappled first with the repercussions of the COVID-19 pandemic, and subsequently, with the complexities introduced by the conflict in Ukraine.

The Ukrainian conflict emerged ushering in a new set of complexities. The impact extended beyond the geopolitical realm, affecting the supply chains and access to raw materials, particularly in regions directly influenced by the conflict.

The cascading effect of these dual challenges created a compounded scenario, where the defense industry found itself in a perpetual state of adjustment.

Arseneault vividly described the situation as resembling a chain reaction of falling dominos, where each external factor triggered a subsequent challenge.

Notably, the conflict in Ukraine further exacerbated issues related to raw materials and disrupted supply chains, particularly those extending beyond national borders.

The resulting turbulence affected multiple facets of the industry, with microelectronics production emerging as a focal point of struggle. The demand for these critical components began to surge, placing additional strain on an industry already grappling with the aftermath of the pandemic.

Against the backdrop of the conflict in Ukraine, Arseneault emphasized the evolving nature of discussions within the industry, extending beyond the immediate events to contemplate the medium and long-term implications for the defense of Europe and NATO.

The dual focus on countering the pacing threat posed by China and addressing new challenges arising from the conflict in Ukraine underscores the dynamic landscape that industry leaders must navigate.

Arseneault shed light on BAE Systems’ involvement in the Ukraine conflict, with its M777 Howitzer being a notable asset deployed to the region.

The resurgence of artillery and the role of combat vehicles have become pivotal considerations in shaping defense strategies for Europe, closely monitored by BAE Systems given its significant portfolio in these areas.

As the industry strives to recalibrate and address the heightened demand, Arseneault acknowledged that the current landscape is far removed from the pre-COVID era.

“I think many of us in industry have found ways to work around it to the best of our ability, but we’re nowhere near where we were pre-COVID. Microelectronics is now where we’re having the most supply chain trouble,” Arseneault spoke with Defense News in July 2020.

Besides, the ongoing conflict in Ukraine, which has increased demand for defense capabilities such as unmanned aerial vehicles and missiles, putting stress on supply chains.

This drives BAE Systems’ acquisition of Ball Corp.’s aerospace subsidiary for $5.5 billion on Aug 17, 2023, marking BAE’s largest acquisition to date.

To Gain the Upper Hand: BAE Systems – Ball Corp. $5.5 Billion Deal

Tom Arseneault highlighted two broader trends influencing customer budget priorities.

“First amongst these trends is the steady inexorable shift of priority to the space domain where scores of new satellites will orbit the earth to protect and defend our freedoms around the world,” he said.

“Second: increasing concerns about the causes and effects of global warming, catastrophic weather events and the health of our planet at large are also steering budgets to space, where future generations of sophisticated scientific instruments and monitoring systems will help us better understand the earth and our impact on it,” he added.

Ball Aerospace’s role in manufacturing spacecraft, instruments, and sensors for satellites aligns with the shift of priority to the space domain.

The company’s involvement in programs like NASA’s James Webb Space Telescope, the Joint Polar Satellite System, and the Space Based Surveillance System for the Space Force demonstrates its expertise in the space industry.

The acquisition is expected to give BAE a footprint in munitions, an area experiencing historically high demand across Europe. Ball Aerospace, as a merchant supplier to larger companies, both partners and competes with them, especially in the smaller, more modest satellite market.

Arseneault characterized BAE as “being part of the munition supply chain in a world where countries are backfilling more than ever before.”

The deal, expected to close in the first half of 2024, is subject to regulatory approvals.

With approximately 5,200 dedicated professionals, the company is poised to achieve substantial milestones, including an anticipated $2.3 billion in revenue by the end of 2023 and a targeted 10% compound annual growth rate over the next five years.

Bolstered by a formidable order backlog of $8 billion, Ball Aerospace’s market presence spans 85% defense and 15% civil sectors, with a strategic emphasis on space activities comprising 70% of its domain operations.

Notably, the company’s revenue structure reflects a balanced mix of prime contracts with government agencies and sales as a merchant supplier to key defense hardware entities.

Moreover, with a projected 2023 EBITDA of $310 million and an enterprise value adjusted to $4.8 billion, Ball Aerospace is primed for sustained profitability and value creation.

BAE also anticipates $30 million in run-rate cost synergies for 2024 through competitive positioning, procurement savings, and improvements in program execution.

“Executing our strategy of enabling the greater use of circular aluminum packaging on a global scale continues,” Ball CEO Daniel Fisher said. “Our acceleration of low-carbon, best-value aluminum packaging initiatives in the years to come will stimulate organic growth across our global packaging operations and improve the world for future generations.”

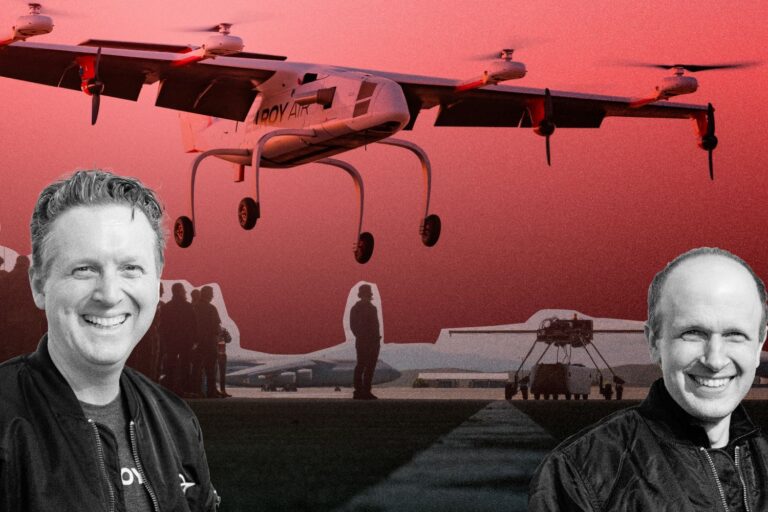

Future-Ready Defense: Innovations in Autonomous Flight and Electronic Warfare

In the dynamic landscape of modern warfare, the U.S. Air Force is increasingly exploring the integration of autonomous aircraft with manned fighters and bombers.

This strategic shift has prompted BAE Systems, under the leadership of Arseneault, to channel resources into its autonomous sector, capitalizing on decades of experience in autonomy-related initiatives.

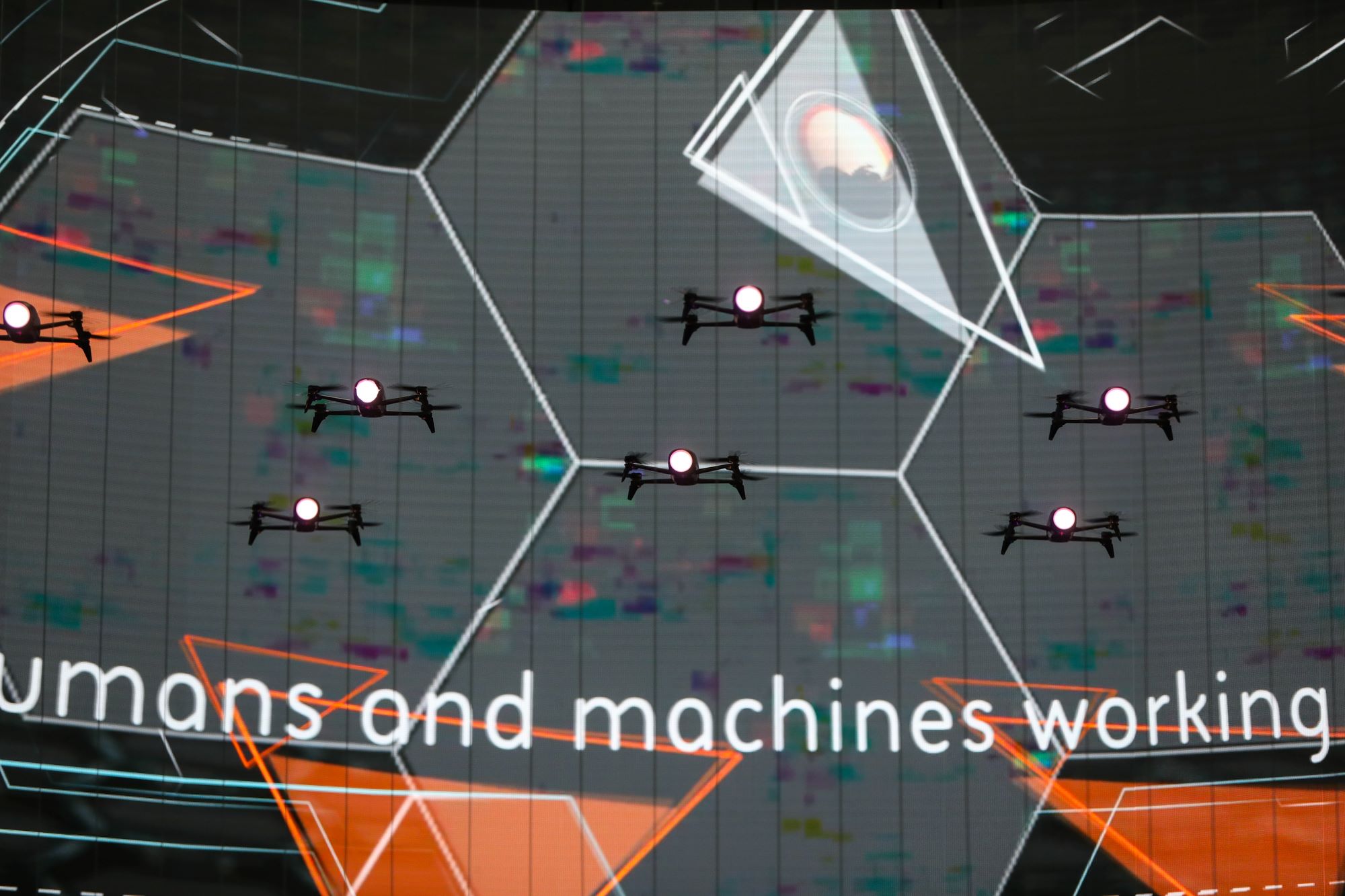

Arseneault acknowledges BAE’s longstanding involvement in autonomy, emphasizing the company’s participation in various programs focused on manned-unmanned teaming.

Drawing on a rich history of developing flight control systems for both commercial and military aircraft, BAE has positioned itself as a key player in the evolving landscape of autonomous technologies.

The concept of manned-unmanned teaming aligns with the future vision of warfare, where a combination of human-operated assets and autonomous systems enhances firepower while minimizing the risk to human life.

Arseneault highlights the company’s proactive approach in aligning with the interests of Air Force Secretary Frank Kendall, keeping him briefed on BAE’s initiatives and technologies in the autonomous domain.

The recognition of real potential in the synergy between manned and unmanned assets reflects BAE’s strategic foresight in contributing to the evolution of defense capabilities.

Beyond autonomous flight, BAE’s involvement in critical defense missions is exemplified by its role in the electronic warfare components of the Air Force’s Compass Call recap.

“Compass Call’s mission has been a bit below the radar, but it has been used in every major conflict of the last 40 years. And it is a critical mission. It performs a series of electronic warfare missions from jamming to suppression of enemy air defense, etc.” Arseneault said.

Arseneault also provides insights into the progress of the EC-37B, the successor to the aging Compass Call EC-130s. It represents a leap forward in capability.

“The EC-37B will be able to fly higher and faster than the old Compass Call EC-130s. The EC-130, from a maintenance standpoint, was pretty costly with some of these aging aircraft. And so it’s time to change the packaging for Compass Call,” he stated.

BAE Systems has unveiled a series of groundbreaking technologies, prominently featuring the Small Adaptive Bank of Electronic Resources (SABER). As the cornerstone of the Compass Call mission, SABER plays a pivotal role in providing the aircraft with a distinctive standoff jamming capability, ensuring a technological edge in the ever-evolving landscape of electronic warfare.

SABER, an acronym for Small Adaptive Bank of Electronic Resources, epitomizes the cutting-edge approach that BAE Systems brings to electronic warfare.

This technology forms the backbone of Compass Call, a mission that has been pivotal in major conflicts over the last four decades. Standoff jamming, a crucial component of Compass Call’s capabilities, is significantly enhanced by the adaptable and resource-efficient nature of SABER.

A noteworthy development under Arseneault’s leadership is the introduction of an exportable version of SABER, a testament to BAE Systems’ commitment to bringing its advanced electronic warfare capabilities to the international stage.

This exportable version is poised to feature prominently at prestigious events such as Farnborough, showcasing the company’s technological prowess and its potential impact on global defense scenarios.

“I think standoff jamming as a mission, has quite a bit of relevance in some of these future fight scenarios. And so we’ll be able to bring our standoff jamming capability into the international arena,” said Arseneault.

Furthermore, BAE Systems has initiated a pioneering initiative to revolutionize aircraft manufacturing at its facility in Warton, Lancashire. The transformation involves the conversion of an old hangar into a cutting-edge test bed for the development of the Tempest, the next-generation combat aircraft slated for service with the Royal Air Force by 2035.

Central to this endeavor is the concept of a “factory of the future,” where advanced manufacturing techniques, robotics, and digitalization converge to redefine the traditional aircraft production process.

BAE Systems, alongside partners such as Rolls-Royce, Leonardo UK, Siemens, and numerous smaller suppliers, is spearheading a collaborative effort to streamline and accelerate aircraft development.

The overarching objective is ambitious: to design and manufacture the Tempest in significantly less time compared to previous aircraft programs. This necessitates a paradigm shift in how combat aircraft are conceptualized, engineered, and constructed.

Dave Holmes, BAE’s technology and manufacturing director, underscores the importance of increased automation and the implementation of a “digital thread” that seamlessly integrates data from concept to production.

At the heart of the factory, engineers are leveraging state-of-the-art robotic technology to fabricate a prototype of the aircraft’s front fuselage with unprecedented precision.

By enhancing the accuracy of standard robots tenfold, BAE and its collaborators are pushing the boundaries of what is achievable in aircraft assembly.

Tom Arseneault’s Perspectives on Inflation and Modernization

As the debate over the 2023 budget unfolds, Tom Arseneault provides valuable insights into areas of concern and considerations within the defense landscape.

Congress, recognizing the impact of inflation on the buying power of services, is emphasizing the need to modernize for the future while sustaining legacy systems, aligning with the National Defense Strategy priorities.

Arseneault acknowledges the upward pressure on budgets across the board as they progress through committees, expressing cautious optimism about the direction of the budget discussions.

However, he highlights the complex challenge posed by inflationary pressures on the Defense Department and its potential impact on procurement amounts for key weapons systems in 2023.

The CEO emphasizes that the effects of inflation will vary across the broader portfolio, necessitating a delicate balance in decision-making.

In some instances, recognizing the upward trajectory of prices for the same number of aircraft or systems may be necessary. The crucial question becomes how to navigate the budget constraints while ensuring modernization efforts align with strategic priorities.

Arseneault underscores the importance of finding the right balance and notes that each service branch is working through its assessment of what can be afforded amid these challenges.

“In other instances, there will be a balancing act around how far can that money go? What can we afford? Each of the services are working through their sense of that, but I think Congress recognizes that the budget needs to account for the inflation that we’re experiencing, which we haven’t seen in the better part of 40 years,” he said.

“There’s a number of factors at play working its way into the decision, much as you and I and everyone who is paying for gasoline and groceries these days is experiencing,” he added.

Inspiring the Next Generation: BAE Systems’ Commitment to STEM

Arseneault has also undertaken a compelling quest to champion STEM (Science, Technology, Engineering, and Mathematics) education, recognizing its paramount importance in shaping the future of not only the company but also the nation and the world at large.

At the heart of his vision lies a profound understanding of the critical role that STEM professionals play in driving innovation, solving complex problems, and propelling technological advancements forward.

With this understanding comes a deep commitment to nurturing and empowering the next generation of STEM leaders, innovators, and problem solvers.

The CEO’s quest on STEM education is multifaceted and driven by a clear purpose: to inspire, educate, and support students in their STEM journey from a young age.

By partnering with organizations like FIRST™ (For Inspiration and Recognition in Science and Technology), BAE Systems actively engages in initiatives that foster hands-on learning experiences, mentorship opportunities, and real-world application of STEM principles.

Through strategic investments, sponsorships, and volunteerism, BAE Systems under the CEO’s guidance is not only supporting STEM programs but also actively participating in shaping their trajectory.

In 2023, BAE Systems solidified its commitment to fostering STEM education and innovation by assuming the role of the presenting sponsor for the prestigious FIRST national championship held in Houston, Texas.

The event, which drew participation from over 18,000 students representing 59 countries, stands as the pinnacle of STEM celebration globally. This vibrant gathering not only underscores the remarkable achievements of the participating students but also highlights the enduring legacy of FIRST and its visionary founder, Dean Kamen, whose foresight in the early 90s laid the groundwork for this monumental initiative.

At the heart of the FIRST Robotics Competition lies an unparalleled dedication to ingenuity and teamwork. Teams comprising students from diverse backgrounds embark on a journey marked by meticulous planning, collaborative effort, and unwavering determination.

From the inception of the competition, students delve into the intricacies of CAD design, meticulously sculpting their vision into tangible reality. Armed with creativity and technical prowess, they navigate the complexities of material selection and fabrication, transforming raw components into robots that stand as marvels of modern engineering.

The journey of a FIRST Robotics team extends beyond the workshop. As students immerse themselves in the realm of software development, they meticulously craft algorithms and programming sequences that empower their creations to respond with precision and agility. Sensor feedback becomes their guiding compass, steering their robots through a myriad of challenges and tasks with grace and finesse.

“I’m so proud that we’re helping prepare students to make a difference in the future of our industry and many others. Our partnership with FIRST will continue to inspire, teach, and open doors to the exciting potential of a career in a STEM field, and that will yield benefits for the nation and our communities for generations to come,” Arseneault stated.