How Does the Inside Technology of Elroy Air Aligns with the DoD Critical Missions?

Jets on the battlefield tackle some of the most perilous missions, each fraught with excitement and risk. They soar into enemy territory for high-stakes reconnaissance, gathering vital intelligence while evading sophisticated defenses. In precision airstrikes, they deliver powerful blows to enemy targets with pinpoint accuracy, threading the needle between decisive action and collateral damage.

Combat air patrols see them engaging in thrilling aerial dogfights, defending against enemy aircraft with cutting-edge tactics. Close air support missions bring them dangerously close to ground battles, providing crucial firepower amidst the chaos. Every mission demands a blend of skill, courage, and strategy, navigating a world where the stakes are incredibly high.

In the high-stakes world of battlefield missions, drones emerge as game-changers, offering a blend of precision and safety.

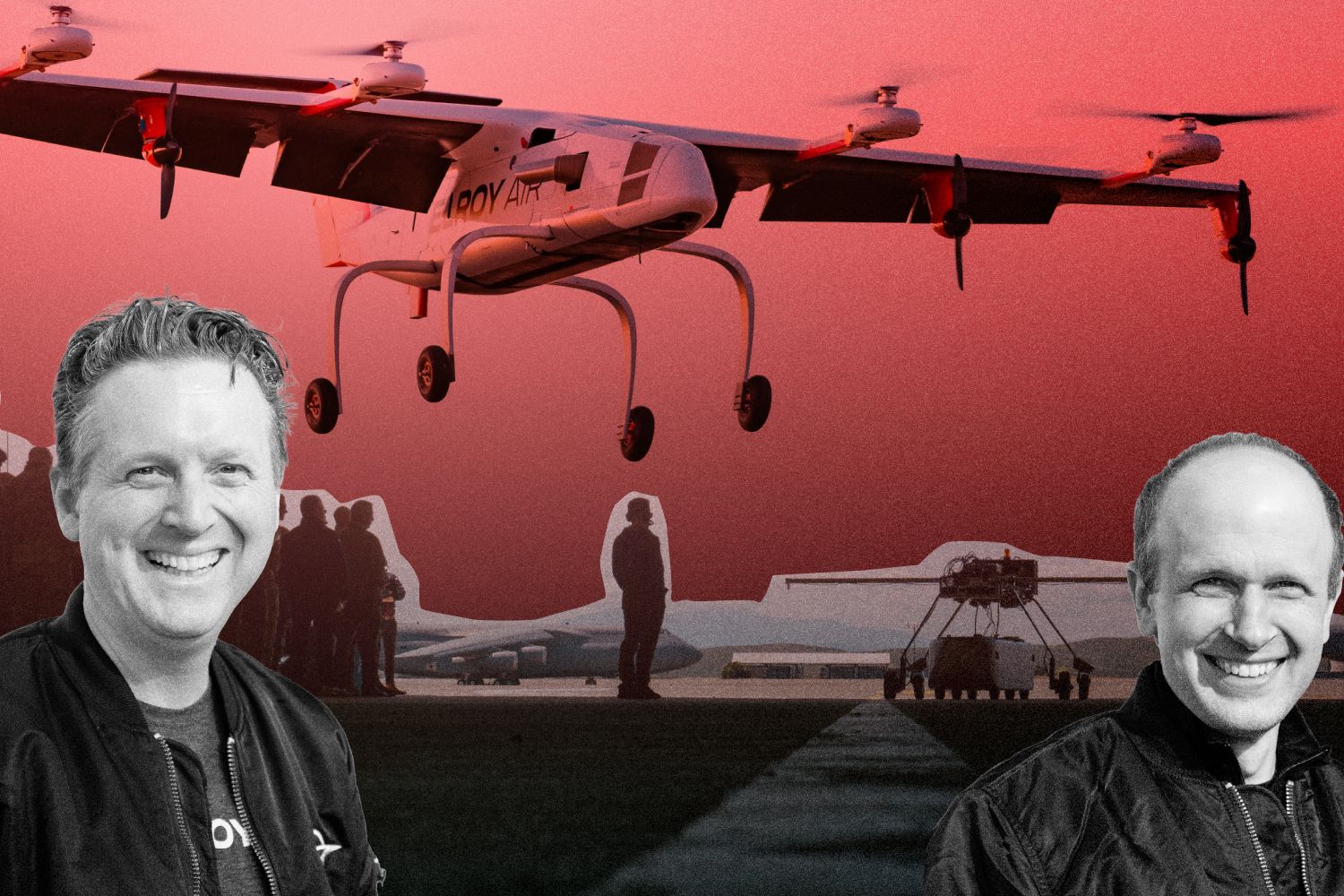

This is where Elroy Air steps in to make a difference. Elroy Air is a logistics firm that focuses on logistics, robotics, and air transportation. Their air cargo system utilizes rotor-based vertical takeoff and landing (VTOL) and shifts to wing-based cruise flight for extended ranges.

Before getting into how the company has brought to the battlefield, let’s take a look at how it came to be.

David Merril and the Passion to Build Masterpieces

David Merrill is an engineer and technologist who grew up building things, inspired by his father’s carpentry and home projects, which gave him confidence in constructing physical items. He eventually pursued computer science, drawn to the ability to create behavior within computers.

While at Stanford during the early days of Google, Merrill discovered his passion for hardware, software, and systems. Instead of joining Google, he focused on the combination of electronics, sensing, and software to develop useful tools for people.

David Merrill almost pursued an academic career, completing a PhD, but a pivotal moment came during an interview at a research lab in the Bay Area. It’s when the lab leader asked him about this true passion – building things or doing research.

“In my heart, I knew the answer was building things,” said David Merrill.

That’s why he didn’t become a professor but an entrepreneur instead. After earning his PhD from MIT, David Merrill started his first venture which later acquired by 3D Robotics, it was a company focused on commercial and consumer drone systems. This experience deepened his fascination with the practical uses of flying technologies and the possibilities they could unlock. However, due to contrast development directions, he left the company.

He recalled, “The company decided it needed to become a software company and pivoted, which wasn’t as interesting to me. So, I left and went to a venture firm called Lemnos, which invests in early-stage hardware startups. I was their Entrepreneur in Residence, and after six months of coaching the other teams, they had invested in, helping to develop some internal curriculum with them, and vetting deals, I started Elroy Air.”

David Merril founded the company with Clint Cope after having the experience at a reasonable level. And now, while the commercial side of the drones is not yet a thing, the potentials to support critical missions proves to be possible.

The Call of Critical Missions

In a nutshell, Elroy Air is developing industry-first autonomous aircraft systems and cutting-edge software, revolutionizing the world of express shipping.

Since its inception, the company has raised over $104.9M from investors like Shield Capital, Catapult Ventures, and Lockheed Martin Ventures. The team has grown to over 80 people, with engineering talent from prominent aerospace companies. Their customers include FedEx, the U.S. Air Force, and other major aviation and humanitarian organizations.

The company has more than 1,000 systems in its demand backlog for its Chaparral aircraft and is focused on moving from prototype testing to full-scale production.

With the mission at to extend the reach of express logistics to every person on the planet, Elroy Air leverages hybrid-electric and autonomous vehicle technologies, their vertical-takeoff-and-landing (VTOL) aircraft transcend traditional airport limitations, unlocking new frontiers in commercial air shipping, humanitarian aid, and military logistics. We will get into the critical missions.

For Humanitarian Aid – Reduce Transportation costs, Increase Essential Supplies Funds

In 2022, AYR Logistics, an experienced aircraft owner and operator with over 20 years of providing logistics support to humanitarian organizations in more than 45 countries—including the United Nations, World Food Programme (WFP), governments, and NGOs—has signed an agreement with Elroy Air to purchase up to 100 Chaparral aircraft. This purchase is intended to enhance and expand AYR’s humanitarian logistics operations.

Stephen Lyons, Chief Development Officer of AYR Logistics, explained that transportation costs reduce the funds available for essential supplies like food and medicine, yet transportation is crucial for delivering aid where it’s needed.

By adopting unmanned aerial cargo vehicles like the Chaparral, AYR expects significant improvements in cost efficiency and operational safety, especially in challenging terrains and conditions where runways and personnel are not always available. Lyons highlighted that the Chaparral is unique in the commercial market for its load-carrying capacity, range, and ability to operate with minimal infrastructure, marking a significant advancement in UAV technology.

“We have designed an aircraft that behaves like a hybrid between a rough-and-ready helicopter and a battle-hardened bush plane, which can pick up cargo up anywhere with a 50 square foot landing area,” said Clint Cope, Co-founder and President of Elroy Air.

He added, “The Chaparral will be a vital logistics link for people around the world with unreliable roadways and in remote and rural areas that take longer to reach today.”

For Defense – De-Risking Resupply Missions

When it comes to defense, Elroy Air will serve resupply missions for soldiers in hard-to-reach, dangerous places.

As shared by David, “The aircraft is autonomous, built to carry 300 pounds over a 300-mile range. One of its special features is vertical takeoff and landing, so like a helicopter, it can go straight up, cruise to a new location, and go straight down. This means it doesn’t need to operate from an airport or runway, giving it a lot of operational flexibility.”

He added, “For defense, de-risking resupply missions in contested environments is hugely important. Today, resupply missions are done using trucks on the ground, which can encounter IEDs and dangerous missions, or helicopters in the air, which can also be in the line of fire and are risky. There’s really no price you can put on human life, so being able to send an aircraft with no person on board to deliver goods on a battlefield is transformational for defense.”

Elroy Air has solidified its reputation as a trusted entity in the defense industry by combining advanced technology, strategic partnerships, and distinguished endorsements. The company’s credibility is further enhanced by its active involvement in high-profile defense exercises and partnerships.

Elroy Air’s recent demonstration of the Chaparral at Mobility Guardian 2023 showcased its capabilities in a real-world setting, highlighting the system’s effectiveness in autonomous cargo handling and aligning with the U.S. Air Force’s goals for Agile Combat Employment.

The company also holds three active contracts with the U.S. Air Force and a Cooperative Research & Development Agreement with U.S. Special Operations Command, which underscores its integration and reliability within the defense sector.

Adding to this robust foundation is Elroy Air’s distinguished advisory board, composed of former senior defense leaders such as Rear Admiral Lorin Selby, The Honorable Ellen M. Lord, General Richard D. Clarke, and Lieutenant General H.R. McMaster.

Their involvement provides Elroy Air with exceptional strategic guidance and insight into defense acquisitions, helping the company navigate the complexities of the defense market and secure substantial opportunities. Their endorsement further cements Elroy Air’s position as a trusted and innovative partner, capable of addressing the evolving needs of military logistics and operations.

Retired Lieutenant General H.R. McMaster is a seasoned U.S. Army officer with a distinguished career as a military strategist and historian. He also served as the 25th National Security Advisor of the United States.

“Military forces must operate widely dispersed and sustain operations at the end of extended and contested lines of supply,” said McMaster. “Elroy Air is providing an example of what we need to maintain our competitive advantage in defense — disruptive innovation to overcome challenges and ensure the Joint Force’s freedom of movement and action, even in the most austere and strongly contested environments.”

The Story Behind

Elroy Air is aiming to work across various sectors as what mentioned above. To get to that point, the company has been following regulations from the government and embracing technology to transform the business.

100% Made in America

The aerospace and defense sectors have strict compliance regulations that add complexity to the process of developing and manufacturing aircraft. While they will eventually need manufacturing certification to produce type-certified aircraft for national airspace, the current phase of development has less stringent requirements, as shared by David.

He emphasized, “Yes, ultimately, we will need a manufacturing certification to produce type-certified aircraft for use in the national airspace. However, in the near term, we’re in the development phase, so the requirements are different—the bar isn’t quite as high for what we need right now.”

David also explained that due to their involvement with the defense community and contracts with the U.S. Air Force, they must avoid using parts from certain countries, such as China, in their supply chain. This constraint has required them to carefully select partners and subsystems from the beginning of the aircraft’s development to ensure compliance with these regulations.

“From the early days of developing this aircraft system, we’ve had to figure out which partners we can use for subsystems, and avoiding certain parts has been a deliberate decision due to this constraint,” he said.

Embracing Technologies to Transform How We Work

“I’ve always been fascinated by the way we interact with technology. A lot of my research work before I launched into the industry was about building new tools for human-computer interaction and new interfaces, which I find personally fascinating,” said David Merril.

That’s what David described how he is fascinated with technology. And this is the reason for the company digital working style.

Digital Lifestyle in Operations

As shared by David, his business is centered on developing new technologies, such as their autonomous aircraft. Each team involved in the project uses specialized tools for their specific tasks: the software team uses platforms like GitHub to manage requirements and documentation, while the manufacturing documentation is evolving.

Initially, they relied on paper records and spreadsheets, but as the company grows, they are transitioning to an Enterprise Resource Planning (ERP) system. This ERP system will serve as a foundational platform, supporting the integration of more advanced digital tools and applications as the company continues to scale.

David stated, “In aerospace manufacturing, managing the digital lifestyle—from the design, procurement, manufacturing, integration, flight testing, to in-the-field monitoring—that’s all really essential.”

He added, “We’re consciously planning out how we’re going to use these digital tools and their best use over the full life cycle of Chaparral products. Some of the systems and tools that we use, like for system engineering definitions, are to make sure that our vehicle meets specifications, that we understand failure modes, and have a fault tree, engineering software tools and requirements management tools “

Leaning Hard on Simulations

Simulators — they’re sort of like video games for training, research and skill enhancement. Flight and other types of aviation simulators help pilots, air traffic controllers, drone operators and more to gain proficiency and get certified faster, all in a virtual environment. It goes the same way when Elroy Air adopts this method to train their pilots.

“We do a lot of simulation—this isn’t specifically related to the manufacturing, but we do it just to make sure we validate the product functionality. We do software validation, so we build like a software flight environment where we can fly a virtual copy of the aircraft. When we’re flying in that virtual environment, we’re using the actual flight code and the actual control laws that will run the vehicle itself, but first in simulation,” said the CEO.

The startup also uses a “hardware-in-the-loop” (HIL) system combined with software simulation. In this setup, The HIL system, which represents the aircraft’s nervous system on a test bench, includes all the avionics and electrical components that will be distributed throughout the actual aircraft. This setup allows them to run software simulations of the aircraft’s missions while testing the hardware in real-time.

Think of the software simulation as a virtual world where they can run thousands of mission scenarios. By integrating the hardware, they can detect issues that only show up with the real components, like communication bottlenecks or how the system responds if a flight control box fails. This helps them ensure that everything works together smoothly in real-world conditions.

But that’s not the final step of their process, according to David Merril, the third simulation that they do is called an Iron Bird, which is common in aerospace.

“It basically is like the guts of the aircraft, also kind of spread out on the benchtop or in our case, on the back of a trailer. So, we’ve got this big trailer in our shop that holds the engine, the generator, the battery, the power distribution electronics, and then the rotors, and so it’s kind of like a copy of the aircraft, but like installed on a trailer instead of packaged into an aerodynamic shell,” The CEO explained.

He continued, “And so, we can run this thing up—this powertrain, a representative powertrain—all the way up to full power levels of what the aircraft needs to do for flight, and you know, hold it up there, make sure that everything’s working, cycle it up and down the way that it will during an actual flight mission.”

David explains that detailed simulations are essential in aerospace because getting things right is crucial. If something goes wrong during a flight, it can be very expensive and time-consuming. For example, if a prototype crashes, it costs money and delays the project.

To avoid these issues, they use simulations—like software tests, hardware-in-the-loop systems, and Iron Bird tests—to find and fix problems before actual flight tests. This way, they make sure everything works properly and reduce the risk of costly mistakes, especially since there won’t be a test pilot on board to handle any issues during real flights.