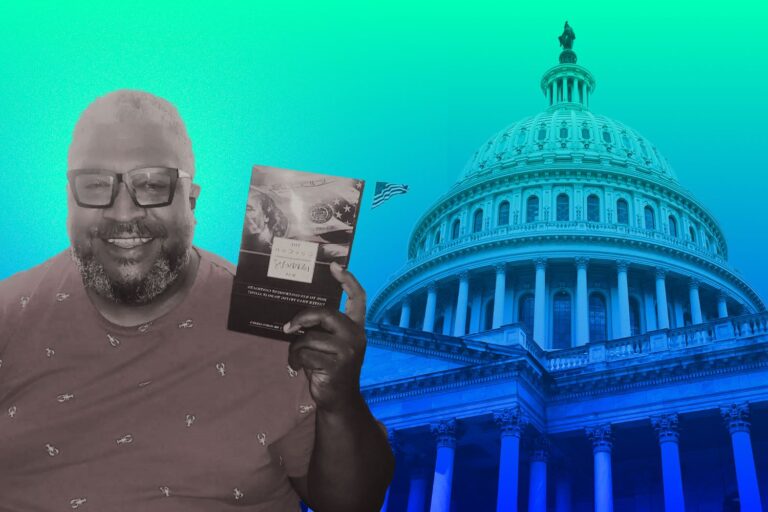

Fred Carl’s Take on Government Contracting – Aiding Warfighters with Ergonomics

Having expertise in specific areas like weapon design, marketing, product development, project management, and supply chain management is crucial in government contracting. This is because the government buys everything, and you can use your expertise as the silver bullet to get contracts.

This is the plot of Fred Carl’s story, where he leveraged his expertise in product design and a niche in ergonomics to provide tailor-made solutions for warfighters. This is also the reason for his success in the government contracting game.

Let’s get to know Fred and his remarkable journey!

Fred Carl – From a Product Designer to Government Contract

Fred Carl has had a rich and varied career in product development. He has been running his company, Gears PDM for nearly six years, having started it in 2019. Before founding his company, Fred spent three years in the firearms market, where he gained valuable experience. Prior to that, he worked in outdoor product development, focusing on knives, tools, and gear.

His journey as a product designer began with developing ideas and bringing them to life, which led him to specialize in ergonomic products within the medical industry. This role allowed him to collaborate with some exceptional surgeons and create innovative medical products.

He recalled, “I grew up as a product designer, developing ideas and making those products come to life. Through that, I developed an ergonomic niche and spent my time in the medical industry, really working with some phenomenal surgeons and being able to develop products and product ideas with them.”

Fred moved to Portland, Oregon, due to his love for mountain climbing and worked with outdoor companies, including Gerber Gear. At Gerber, he spent five to six years developing tools and gear for military use, gaining insights into the needs of soldiers and Marines.

“We worked on saws, tools, knives, weapon kits, weapon tools, and got to understand how the soldier, warfighter, and Marine used their products out in the field. We developed some really cool products from that, and I’ve got to say, my career has been a lot of fun,” he said.

Despite not having military experience, Fred and his team built trust with soldiers using Gerber products. This trust allowed them to directly interact with soldiers, observe their needs, and gather insights.

One notable observation was that soldiers were using Gerber tools for weapons cleaning and maintenance, even though it was not officially sanctioned. This led Fred and his team to develop a specialized tool for weapons maintenance, specifically for the M16. They created a prototype that was eventually authorized and went through the NSN process, sponsored by Picatinny Arsenal. The tool became highly useful and was later produced by Otis Tools.

“We developed the idea, had all the little things that were attached to it, and the guys were amazed by it. Eventually, it did have a contract. It’s not made by Gerber anymore—it’s actually made by Otis Tools out of New York,” he shared.

Fred Carl’s expertise lies in hard goods, which include any physical products such as bags, tents, tools, lights, night vision equipment, and electronics. He has worked on diverse projects ranging from equipment for smoke jumpers fighting fires to products used by the Secret Service and Special Operations.

Fred’s niche is in developing rugged, useful products that meet the specific needs of various government agencies. He is also exploring areas like autonomous vehicles, drones, and UAVs, aiming to connect competitive drone craft developers with government applications.

Fred also stresses on the importance of accessories that enhance the capabilities of warfighters and other government personnel, such as waterproof notepads for the USDA. His focus is on tangible hard goods that provide practical solutions for government use.

All of the services mentioned above are offered by his company, Gears PDM, a full-service product development consultancy specializing in hard goods, with over 25 years of experience in design, development, and product marketing.

Fred Carl’s early experience with government contracting set the stage for his journey into the field. As mentioned earlier, his team successfully developed their product through the NSN process. Let’s explore how he achieved this milestone.

How to get a National Stock Number (NSN) for a Product?

Many new manufacturers discover they lack an NSN for their product, a key identifier used by the government to classify and track items.

NSN lookup, or National Stock Number Lookup, is a process used to identify an item based on its assigned NSN number. This type of search is almost exclusively used by government agencies, military personnel, and aerospace companies to find a part’s National Stock Number.

However, this is not an easy process for people who do government contracting, especially newcomers. To get a NSN, Fred Carl suggests that the best route is to secure a sponsor.,

“It can be the long road, but the best route to get there is getting a sponsor,” Fred stated.

This involves demonstrating that the product is worthy of being used by soldiers in combat, at forward operating bases, or on posts. If the product meets a specific need and is deemed necessary, it is more likely to receive sponsorship.

“And that really comes down to whether your product has worthiness to be worn on a soldier’s body during combat, at a forward operating base, or even on a post. If it’s warranted, and it has a need, it’s going to get sponsorship,” he explained.

He added, “We developed products that were interesting but didn’t have a specific need. From a consumer aspect, it would sell, but from the soldier’s aspect, they’d say, ‘Yeah, I’m not going to use that,’ or ‘It’s going to break.’”

How Did Fred Level up His Knowledge on Government Contracting?

Fred Carl has extensive experience in sales, consulting, product development, and government contracting, including developing NSN numbers. Despite his background, he found that working with larger organizations required substantial products that could generate significant sales to be considered for government contracts.

These companies often had minimum requirements, such as selling at least a quarter million dollars annually, to take the risk of jumping into government contracts.

Fred more frequently works with smaller companies, typically in the $5 to $25 million range. These companies often lack the in-house resources and capabilities to develop or innovate products. They might have strong sales capabilities and good contacts, often through veterans who have procurement experience, but they are not product developers. These companies focus on selling commercially off-the-shelf products rather than addressing specific needs or making their offerings more competitive.

Working with large and small companies made Fred understood the challenges in government contracting. This is why he decided to search for courses to improve his knowledge and eventually chose GoClose.

“That’s where I came to GoClose. I noticed that other competitors didn’t talk about the sources sought, RFIs, or even the RFS processes in any meaningful way. The information they provided wasn’t particularly intelligent or actionable,” he said.

Fred Carl learned several key lessons from the GovClose program that enhanced his understanding of government contracting. He discovered that the Request for Information (RFI) process is more effective than traditional bidding due to high competition. The program provided him with deeper research tools and insights, helping him navigate systems like SAM.gov and understand small business opportunities better.

Fred also gained a comprehensive understanding of the depth of small business contracting, uncovering elements he hadn’t encountered before. This knowledge allowed him to enhance his consulting services and better support his clients in the government market.

Insights for Newcomers Who Seek Opportunities with Government Contracts

Having worked in the field for a considerable time, Fred has accumulated a wealth of valuable lessons for newcomers approaching government contracting. The first one is not to be turned down by the certifications that are required.

The SBA Will Help You With Certifications

Government contracting often requires numerous certifications, especially when working directly with federal, state, or local governments. Fred mentions that many companies are hesitant due to the numerous certifications required, but the Small Business Administration (SBA) can assist with these.

“But come to find out, the SBA will help you with stuff like that,” he stated.

Reading and Understanding All Contract Clauses

According to Rick Howard, the founder of GovClose, one of the most important things to do firt is to thoroughly reading and understanding all contract clauses before committing.

Even with years of experience, it’s a need to carefully review each contract. If a company had been more aware of the contract details, they could have avoided issues by addressing problems early on, such as questioning the need for multiple rewrites of schematics.

However, as Fred Carl points out, many companies fail to do this properly because they fear missing deadlines. This fear often prevents them from thoroughly reviewing contract details and seeking necessary clarifications, leading to avoidable issues down the line.

Fred explained, “The biggest part of that was they were afraid of missing the date, and that’s all they were focused on. I said, ‘Well, didn’t you guys just call up the program manager and ask them a couple of questions?’ They said, ‘We never even thought about it.’ So it’s those types of things where some contracts leave a bad taste in the mouth.”

He added, “If they had changed, if they had somebody who had knowledge of reading those contracts and being able to identify the clauses, I guarantee they probably would have still been making the parts today. Not then, but their prime is still making the parts today. But I think it was just mostly they just didn’t know.”

You Can Have Product That’s Made Overseas

According to Fred Carl, many people are unaware that products manufactured overseas can still be sold to the U.S. government, provided they comply with the Buy American Act requirements.

“And something that a lot of folks don’t realize is that you can have product that’s made overseas, and as long as they sit within a Buy American Act compliance, you can sell to the U.S. government,” he said.

This act allows products made overseas to be sold to the U.S. government, provided they meet certain compliance requirements. Specifically, the Buy American Act mandates that a significant portion of the product’s components or labor must be sourced from the United States.

For example, if a product is assembled in the U.S. using some components made domestically, it may still qualify under the Buy American Act, even if other parts are manufactured overseas. This compliance can make it possible for companies to sell their products to the U.S. government, despite not all components being produced domestically.

Be Aware of Your Competitors!

Government contracting is a highly competitive industry. Businesses ranging from small enterprises to large corporations compete for government contracts. The competition is intense not only due to the significant financial opportunities and the often complex, regulated nature of the bidding process, but also because of the many strong competitors in the field.

As noted by Fred Carl, many companies are unaware of their competitors.

He says, “The competition in that market was so high that the reach would have been just—immediately I started ticking off, hey, your competitors are here, and three of them they had never even known about because they’re focused in the consumer market.”

Fred points out that some competitors are highly specialized, focusing on military and law enforcement markets, which can be a significant advantage.

He mentions, “Those competitors were so focused in the military and law enforcement federal side of business that they don’t sell in the consumer market, and they had no idea that they existed.” This specialization allows these competitors to dominate specific niches, making it challenging for new entrants to gain a foothold without a clear strategy.

To understand a specific competitor, Fred has his own strategy.

By reviewing the entire product line, he can identify which products are already being sold to the government and which ones have higher margins and better capabilities. This helps in understanding how competitors are positioning their products and where there might be opportunities to introduce new, more competitive offerings.

He explains, “We look at their entire product line, so we can say, hey, you guys sell to the government this product, why aren’t you selling that product? And it’s a higher margin, higher capability. And then we can add into that subset— a lot of times, there’s a lot of folks that from the GSA standpoint, they can actually get—they’re already in the GSA, they’re already listed, they can actually plug in a new product that potentially could give them more sales.”