Vartega is leveraging its carbon fiber recycling technology and material development expertise to advance polymer feedstocks for powder bed fusion additive manufacturing. Vartega is developing a novel process that will allow thermoplastic powders to be reinforced with carbon fiber while ensuring these materials will produce functional parts in infrared additive systems. This advancement will enable digital manufacturers to realize the full potential of new powder-based hardware platforms to produce parts that perform similarly to injection molded materials at medium volume production rates.

“Vartega is excited to bring advancements to powder bed fusion printing platforms through development in our novel additive materials,” said Alice Havill, Chief Operating Officer at Vartega. “By offering carbon fiber reinforced polymer powders, manufacturers in sectors like UAV and medical prosthetics will realize the benefits of fast, complex and customized 3D printing, while ensuring that their material selection will exhibit the structural integrity required for their product.”

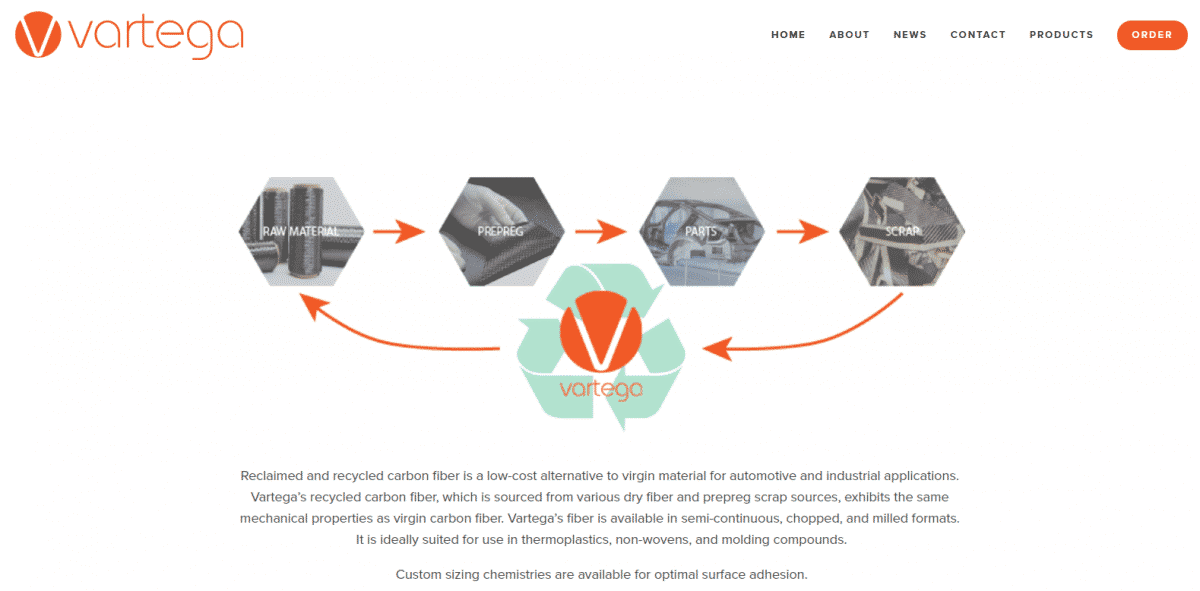

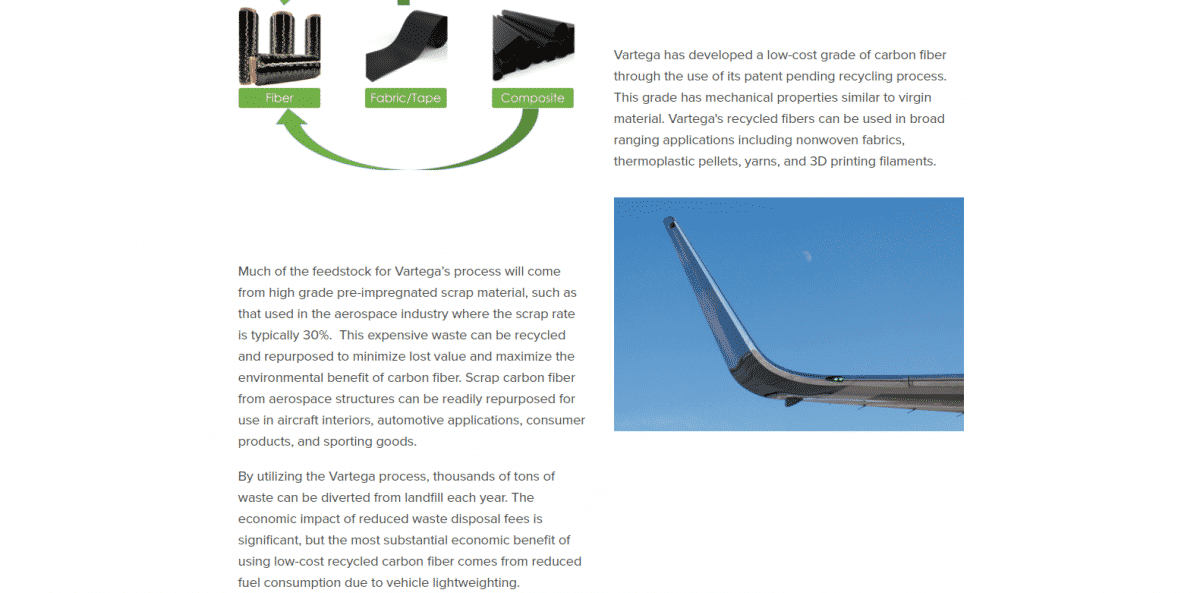

Vartega is a recycler of advanced materials – specifically strong and lightweight carbon fiber. Vartega is cultivating a sustainable future through the development of enabling technologies designed to preserve resources and achieve systematic sustainability. Our modular patent-pending carbon fiber recycling process scales easily to address a gap in the composites supply chain. Vartega’s carbon fiber and specialty thermoplastics are used in sporting goods, additive manufacturing, oil & gas, and vehicle lightweighting.